HEADBAND DEVELOPMENT

The primary design development for the V3 was a foldable headband which reduces the stowed footprint of the headphone to significantly less than that of a conventional design.

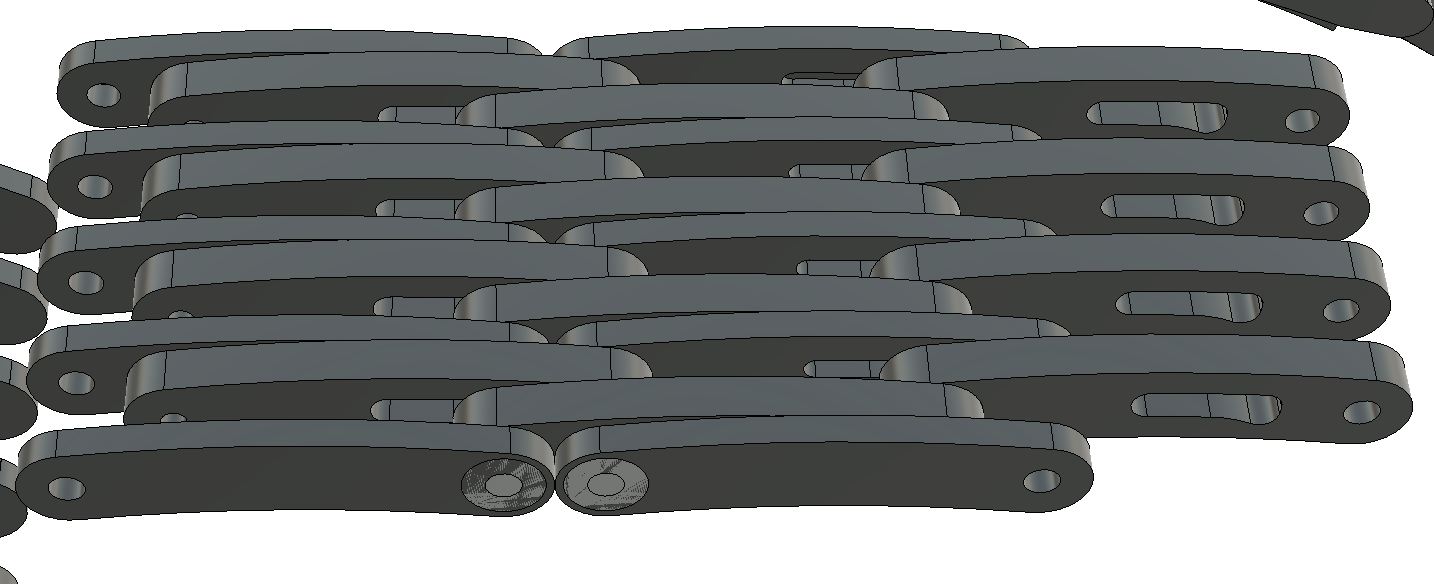

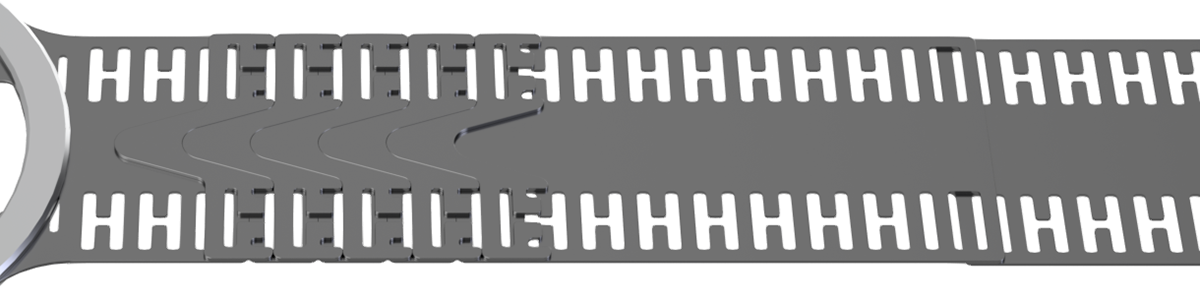

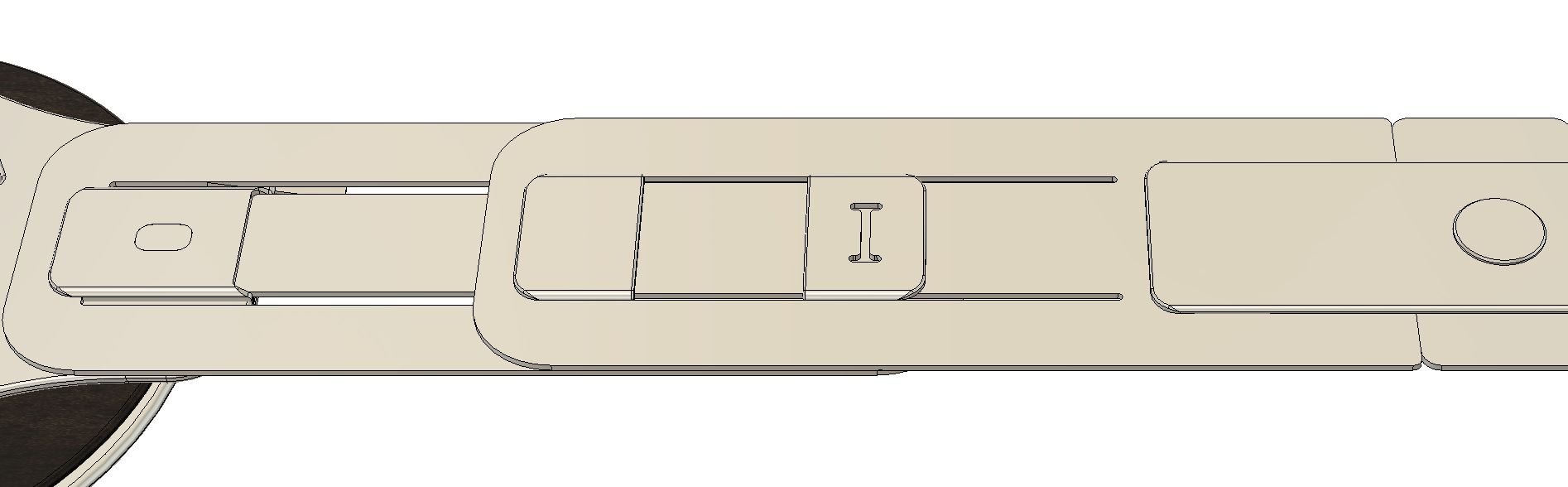

Concept 1: Selectable Flexibility

The first concept is a rigid headband constructed from short segments which are able to pivot relative to one another when unlocked by a sliding mechanism, flattening the segmented body. The first design uses a transverse sliding 'key' to accomplish this, while the second and third are constructed from strips which slide independently and can flatten when aligned. To reduce length, rigid sliding sections attached to each earcup retract over the central body. One benefit of a rigid headband is the reduction or even elimination of clamping pressure, making them fit more akin to a helmet than a pair of headphones. As no prototypes were built the practical effect of this is unknown.

Several manufacturing issues exist with this design, first and foremost the need for each headband to be custom fitted to the wearer; small adjustments can be made by changing the curvature of the strips which attach the earcup, but the majority of the adjustment must be done before the (numerous) components are machined.

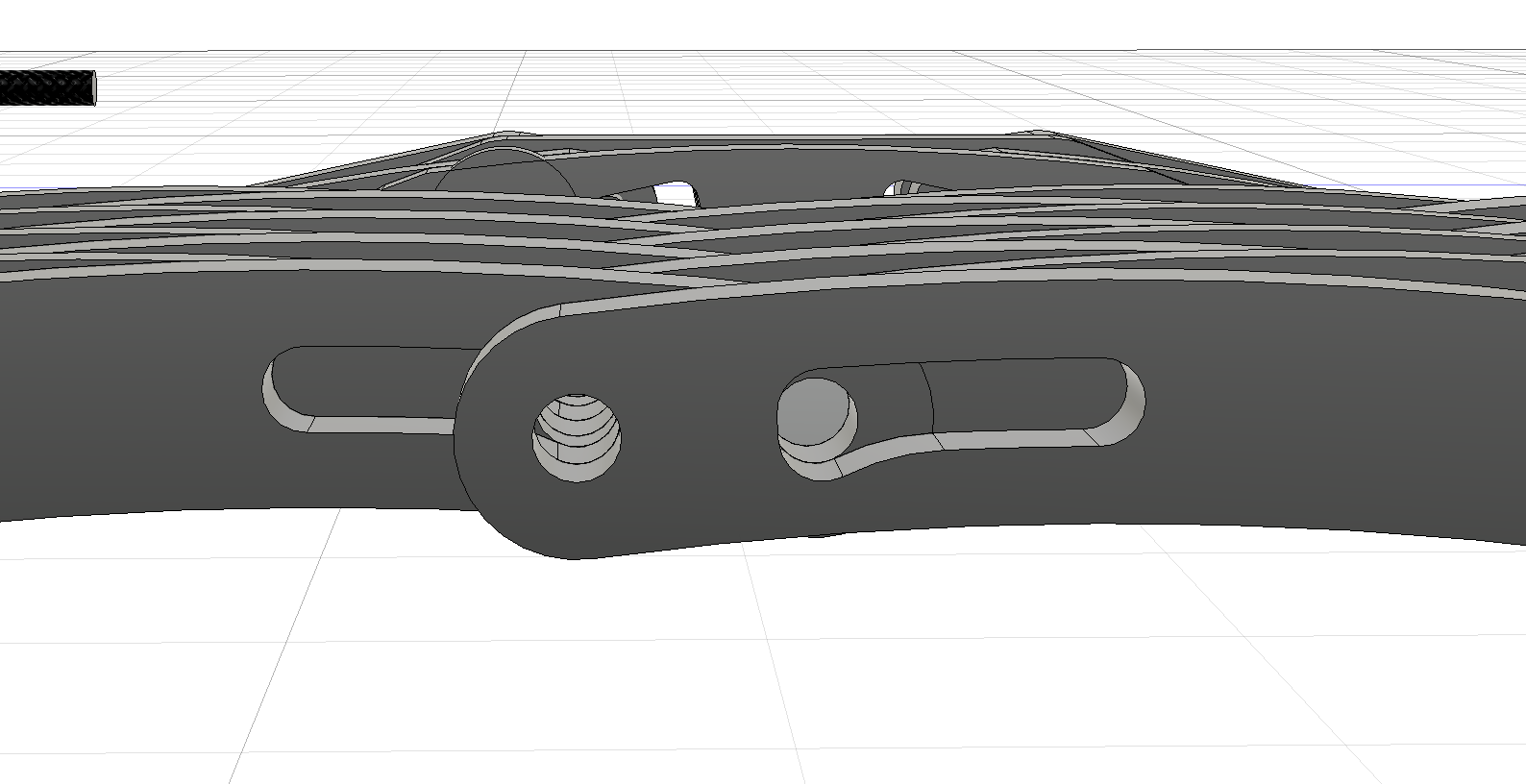

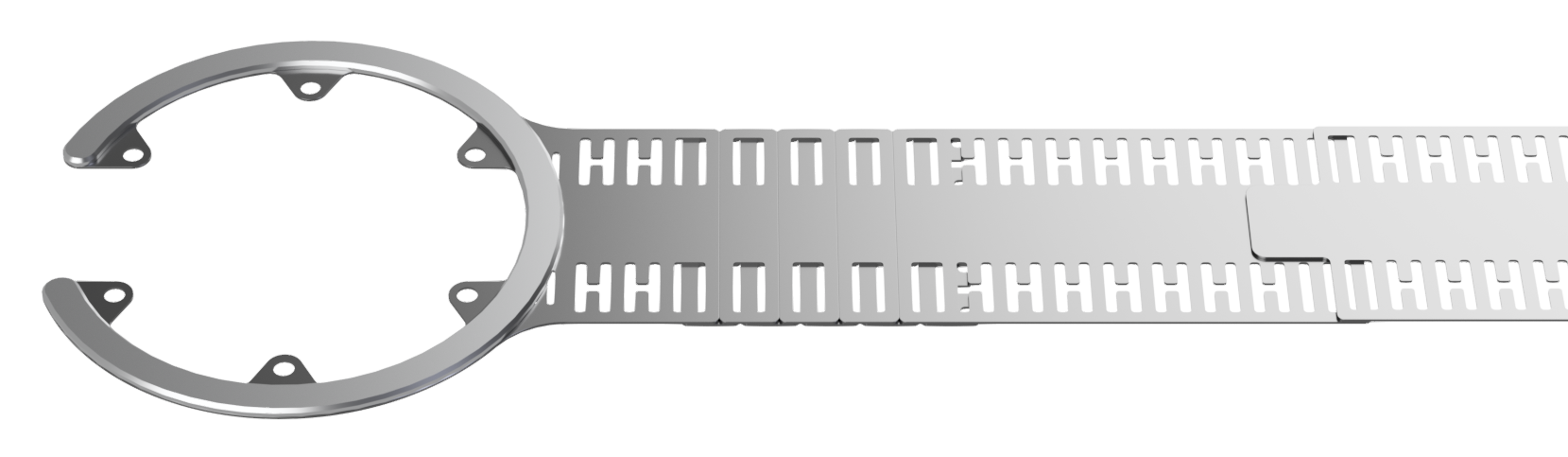

Concept 2: Controlled Tension

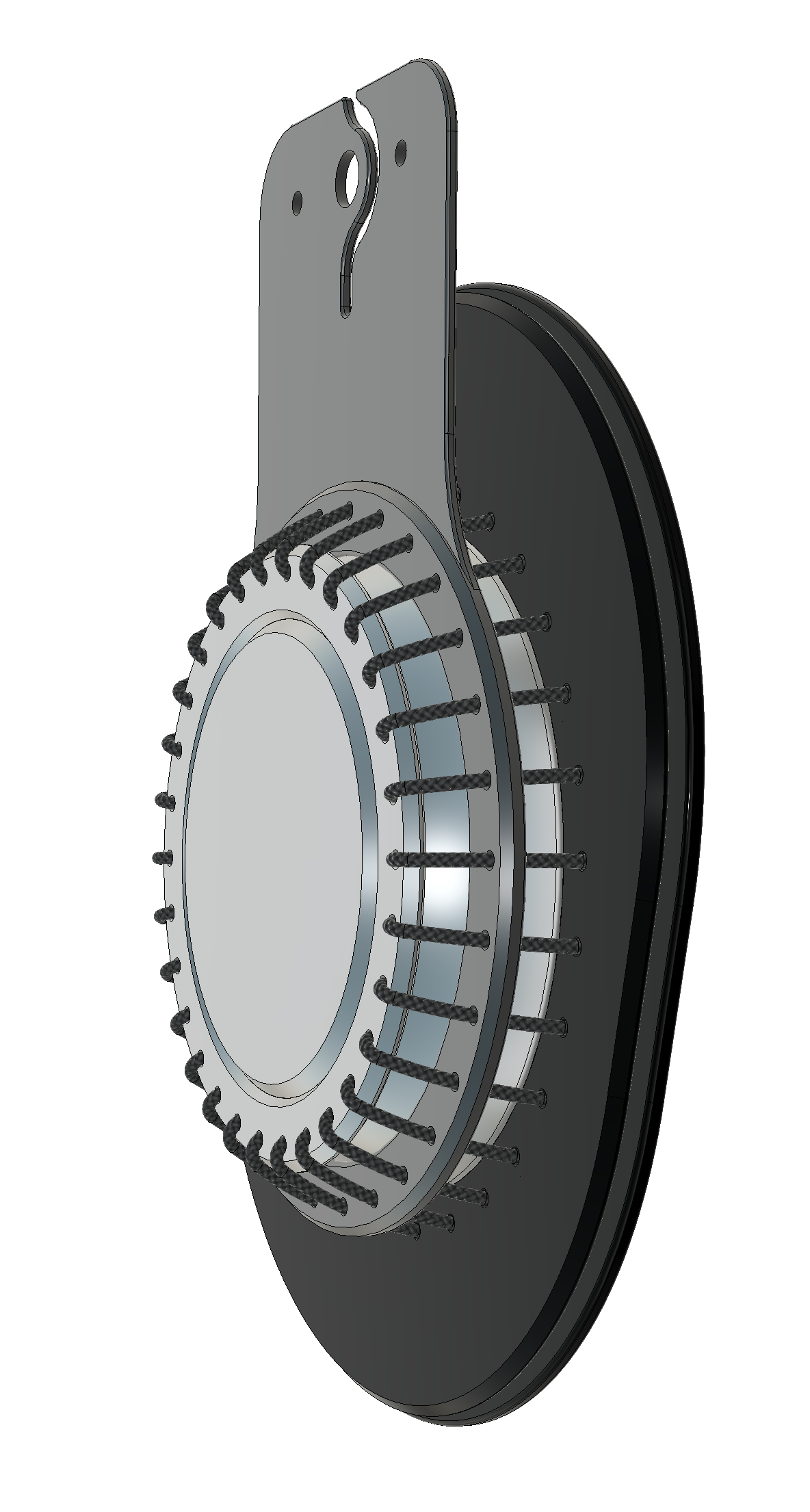

The second concept is based on the principle demonstrated by the prototype in the first picture below. A flexible plate is bent to a predefined curve by a strap affixed to the entire length of its inside face by a cord. By varying the placement and length of each section of the attachment cord, the curvature of the structure can be drastically changed, and can be varied along its length. Folding is accomplished by reducing the effective length of the upper plate, releasing tension in the fabric and flattening the assembly. All three distinct designs focus on different ways to achieve this length reduction.

In contrast to the first concept this strategy does not require custom fitted components, but final length and shape are determined during assembly, a process that is likely too complicated to be completed by the average consumer. Overall number of components is also reduced, with the majority now made from flat sheet metal, resulting in significantly lower manufacturing costs compared to machined designs.

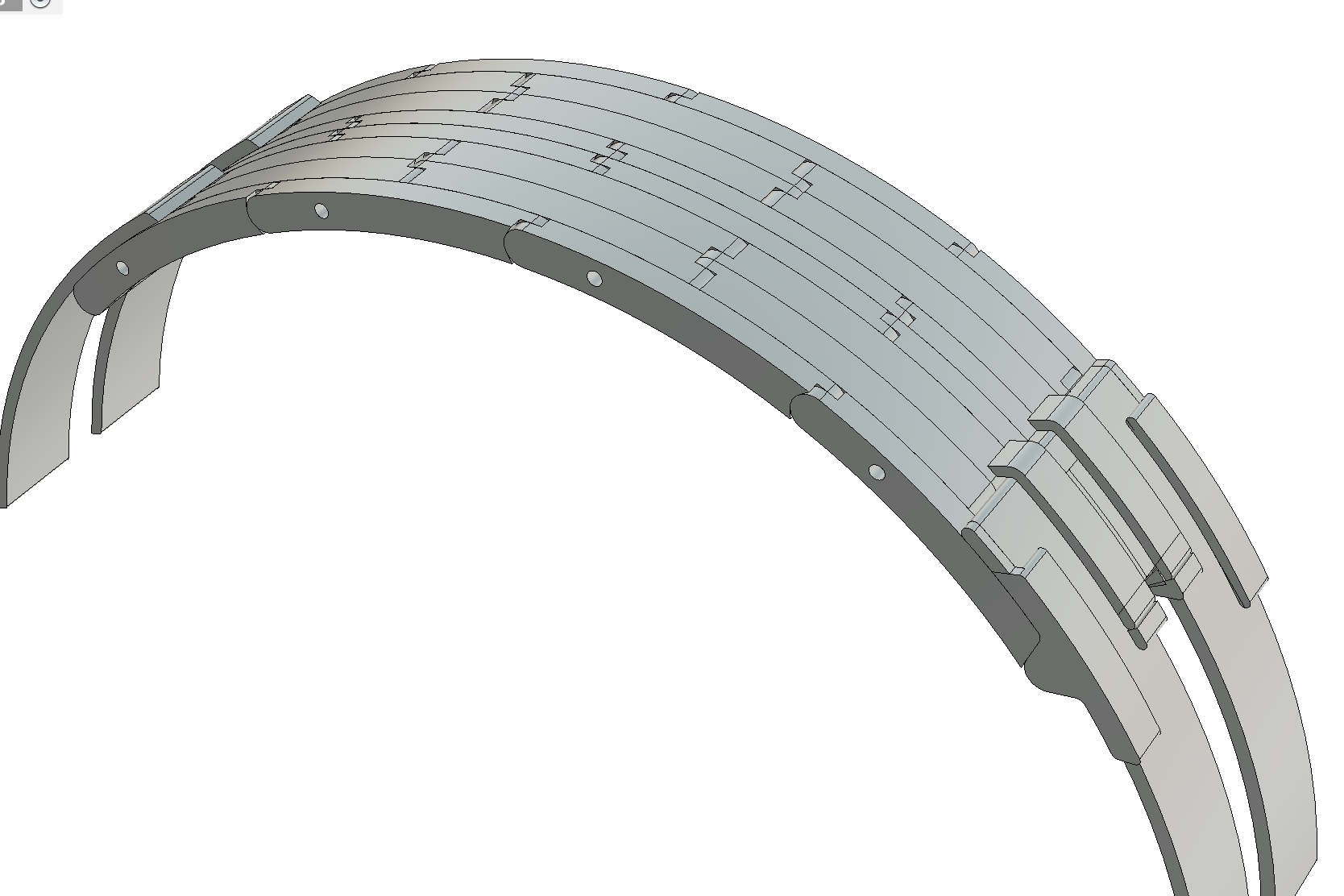

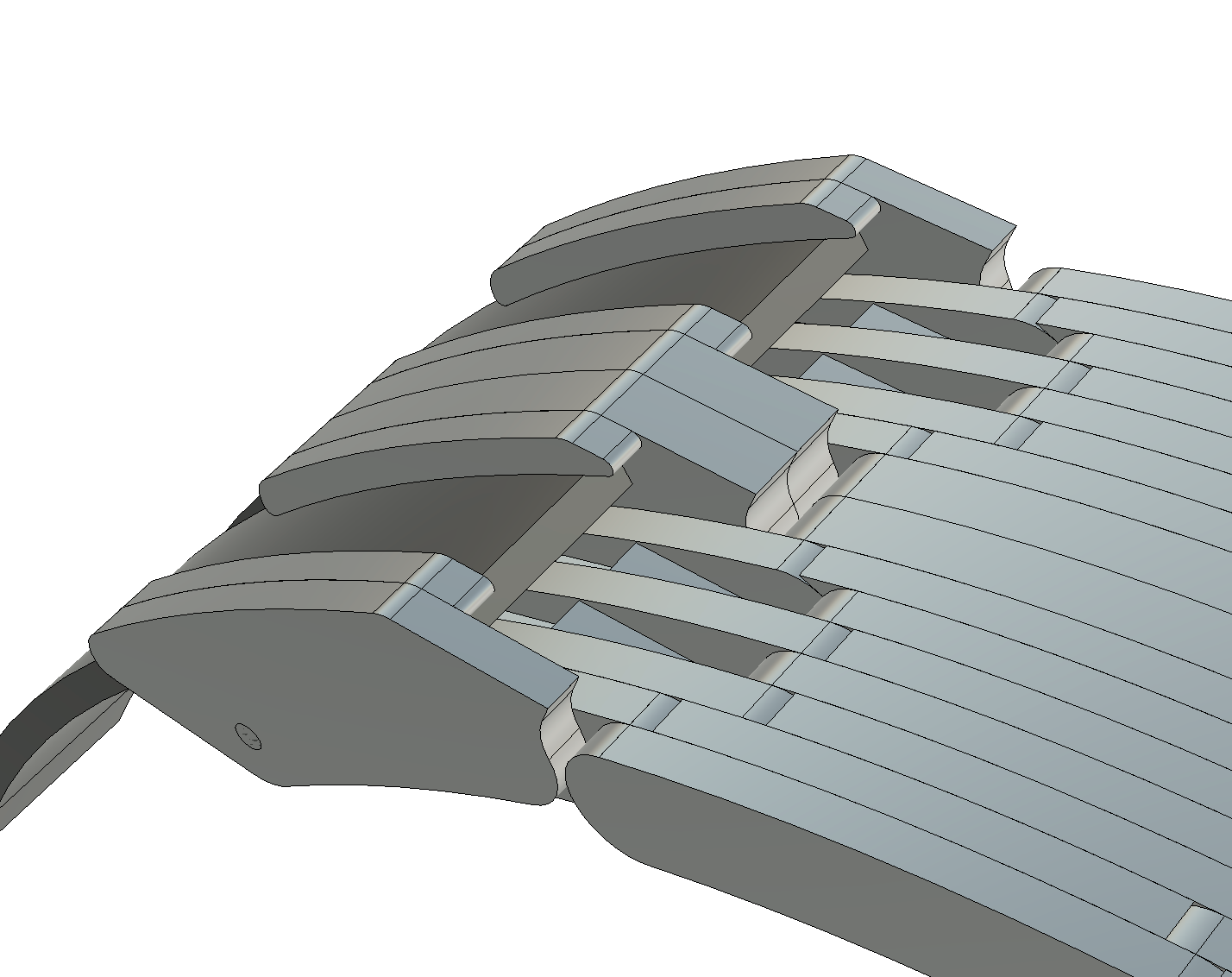

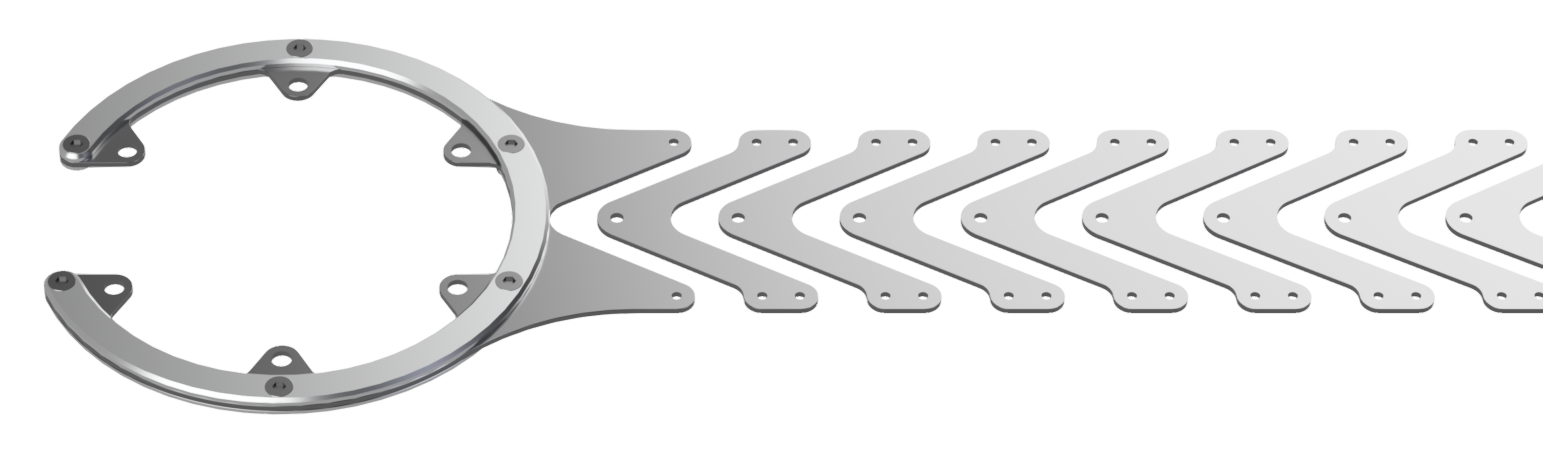

Concept 3: Stacked Curves

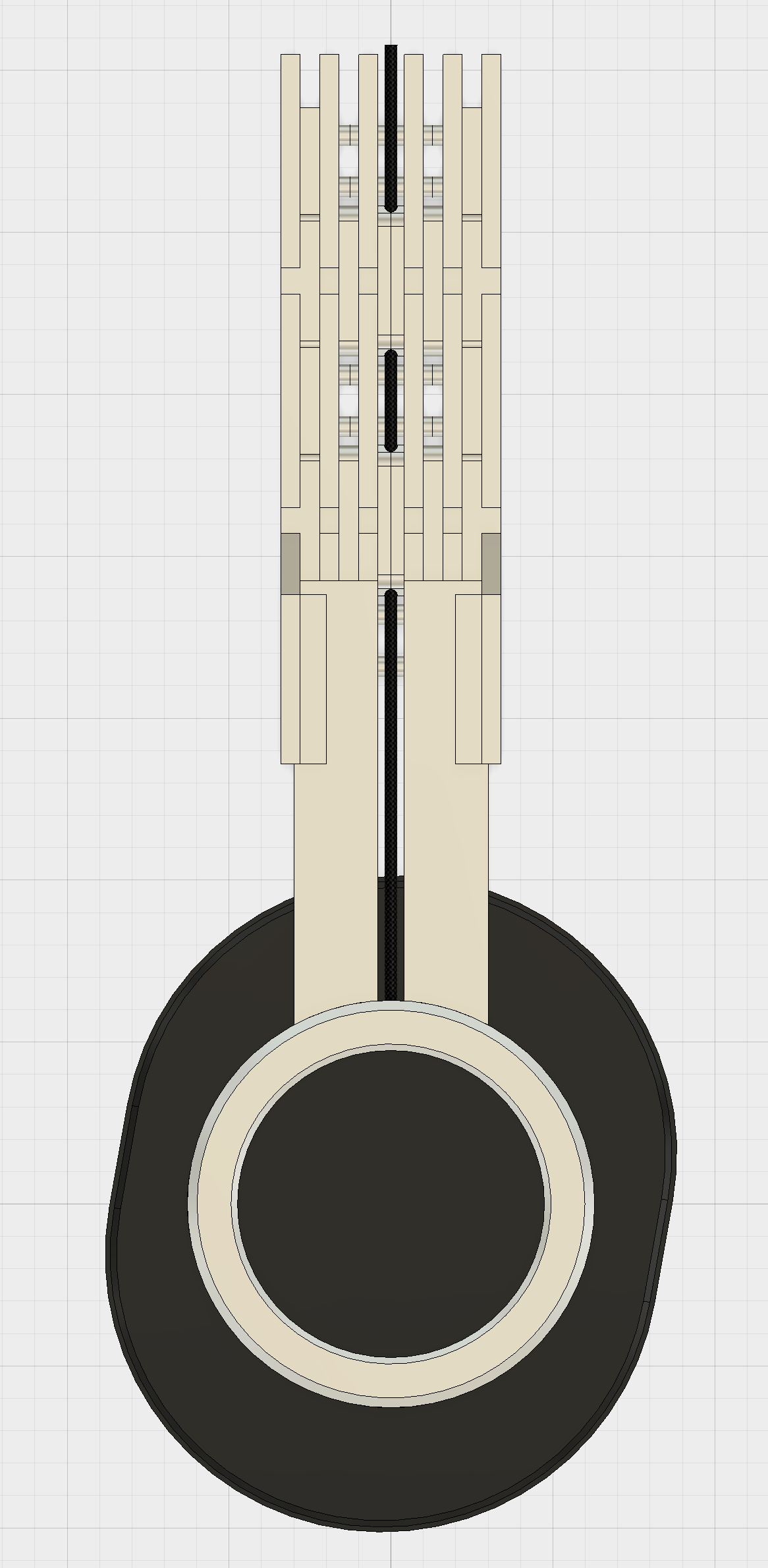

Though arguably the least conceptually interesting, the third and final concept also achieves far greater real world practicality. Instead of requiring the structure itself to flatten, folding is achieved by stacking curved sections on top of each other to reduce end to end length and change in angle, and the remaining curvature is compensated for in the rest of the design. The fabric headstrap is retained, but is now only attached above each earcup and at the center of the headband. When the headband is collapsed the strap folds downwards in a W shape and tucks between the two earcups, or in a flattened C shape when the headband is folded outwards.

Almost all of the headband is made from sheet metal, reducing its thickness when folded and allowing its entire length to bend to the curvature of the wearer's head. The thickness of the sheet metal used is increased from concept 2 however, since the flexibility required is reduced, and the clamping pressure on the head is now applied by the metal structure, rather than tension in the fabric strap.

The head strap consists of two layers, a thicker lower layer which touches the head, and a thinner upper layer, both made from nylon. In contrast to previous designs where the wire connecting the earcups was integrated into the rigid portion of the headband, here it is simply retained between the two layers of the strap. After significant thought and several attempts, I found that regardless of the method of integration, the wire was always bent more harshly when folding the headband than it would be when simply running through the strap. The first rotating design was developed with a built in cable in mind, and removing this requirement allowed for the development of the more compact sliding mechanism.

While the first and second concepts require the headband to be fitted to an individual wearer, both third concept designs are tool-less and exceed the adjustability of most headphones on the market.

EARCUP DEVELOPMENT

Since the design does not rely on the earcups to fold flat to reduce bulk, the vertical hinge from the previous designs can be removed, allowing the headband to more closely follow the curvature of the head when worn. Doing so necessitates an earcup which can articulate in two axes.

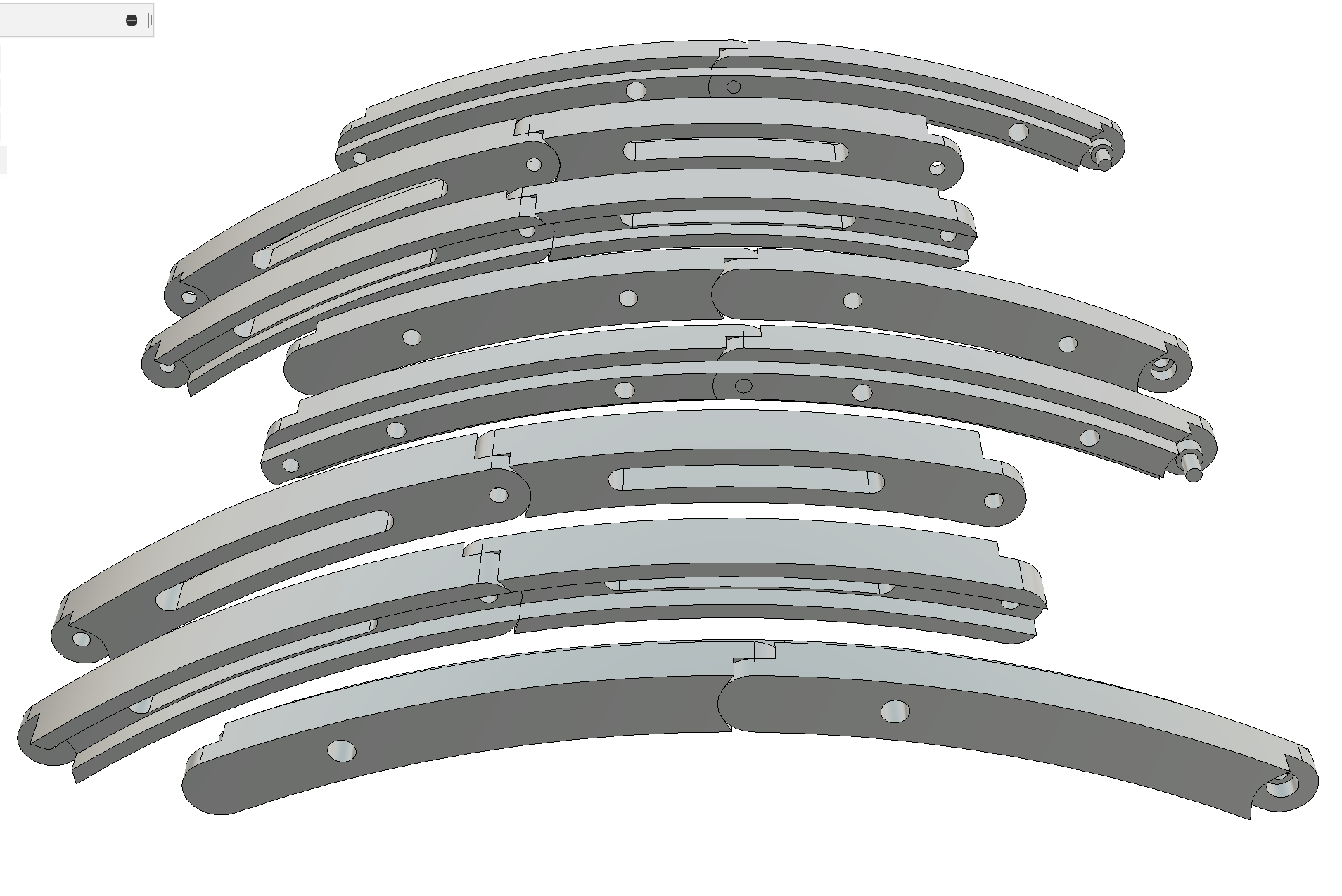

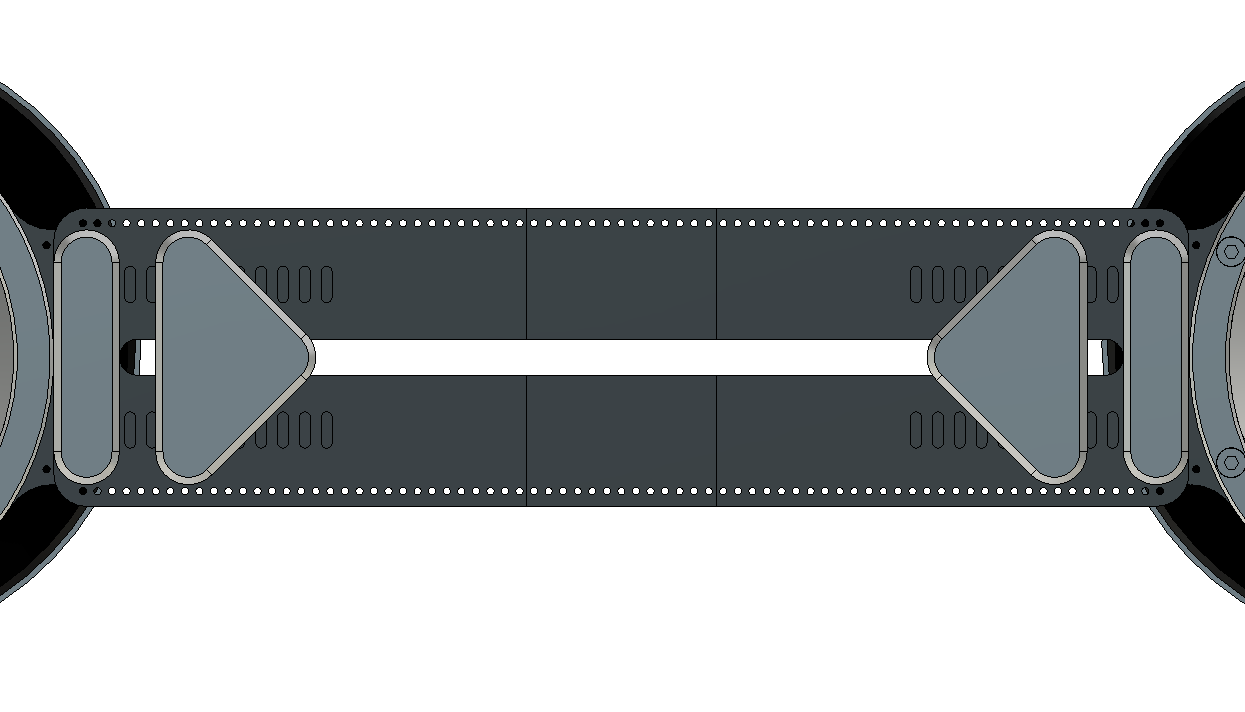

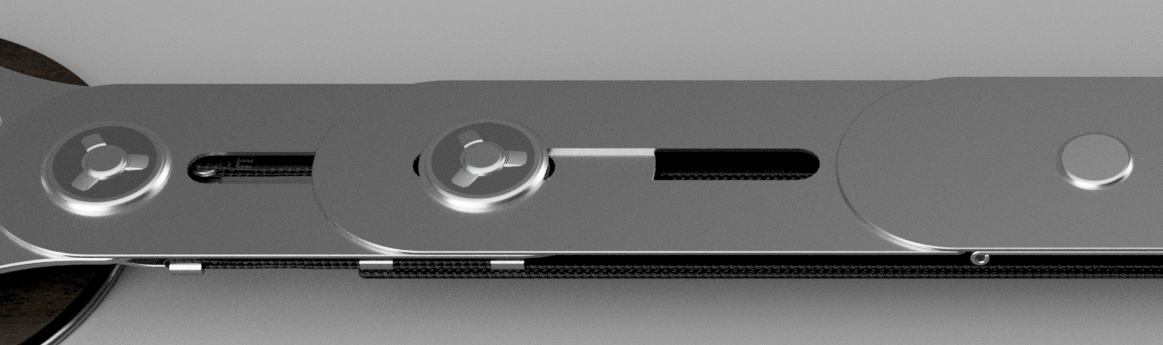

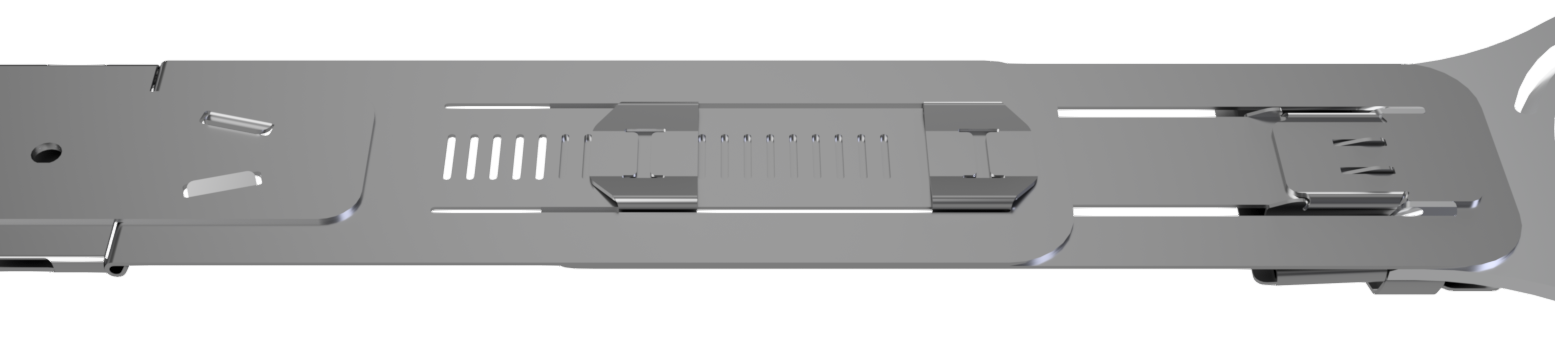

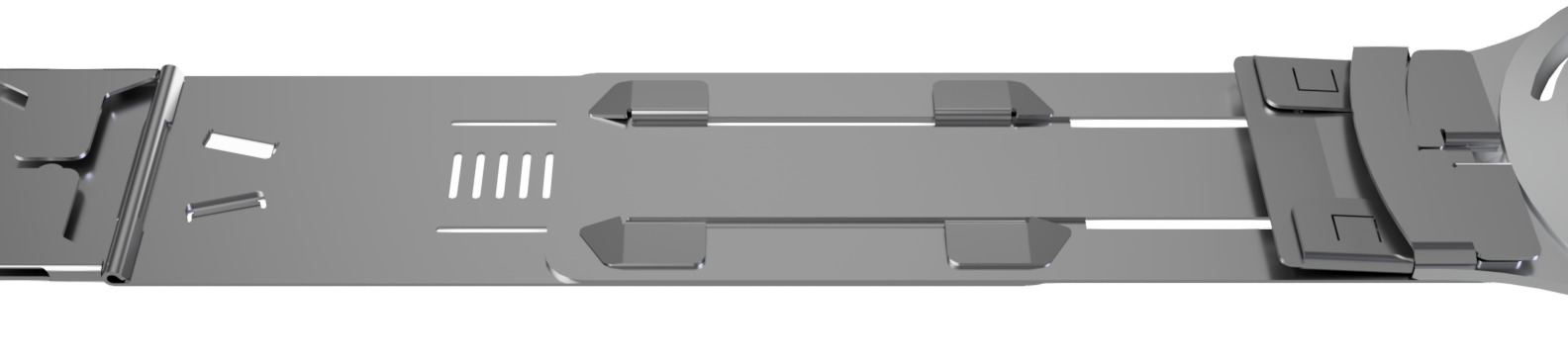

Final Headband

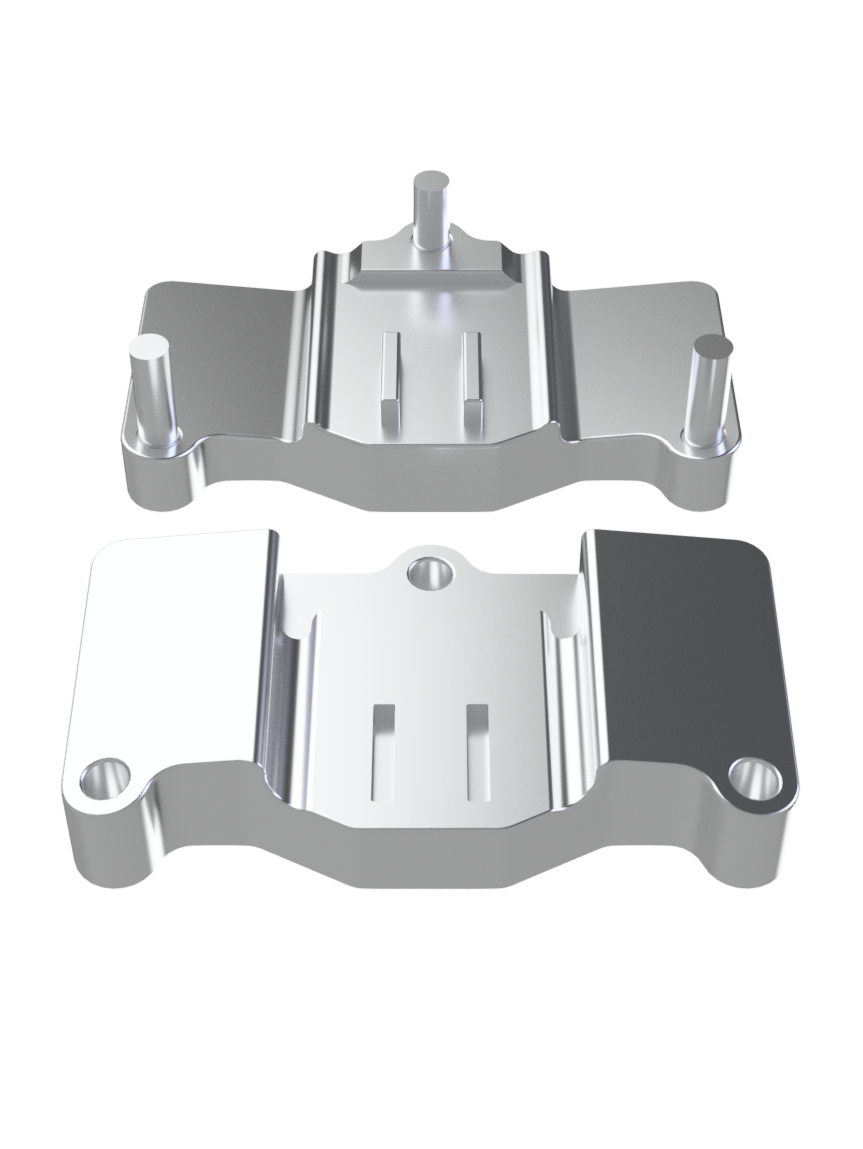

The center of the headband is formed by a small plate with hinges connecting to the adjustment plates on either side. A short plate bridges the center to provide spring pressure and clips into each adjustment plate using two angled slots with matching tabs. To meet the original design goal of folding as flat as possible, this bridge plate rotates 90 degrees, letting the adjacent plates pivot upwards to flatten the center of the headband.

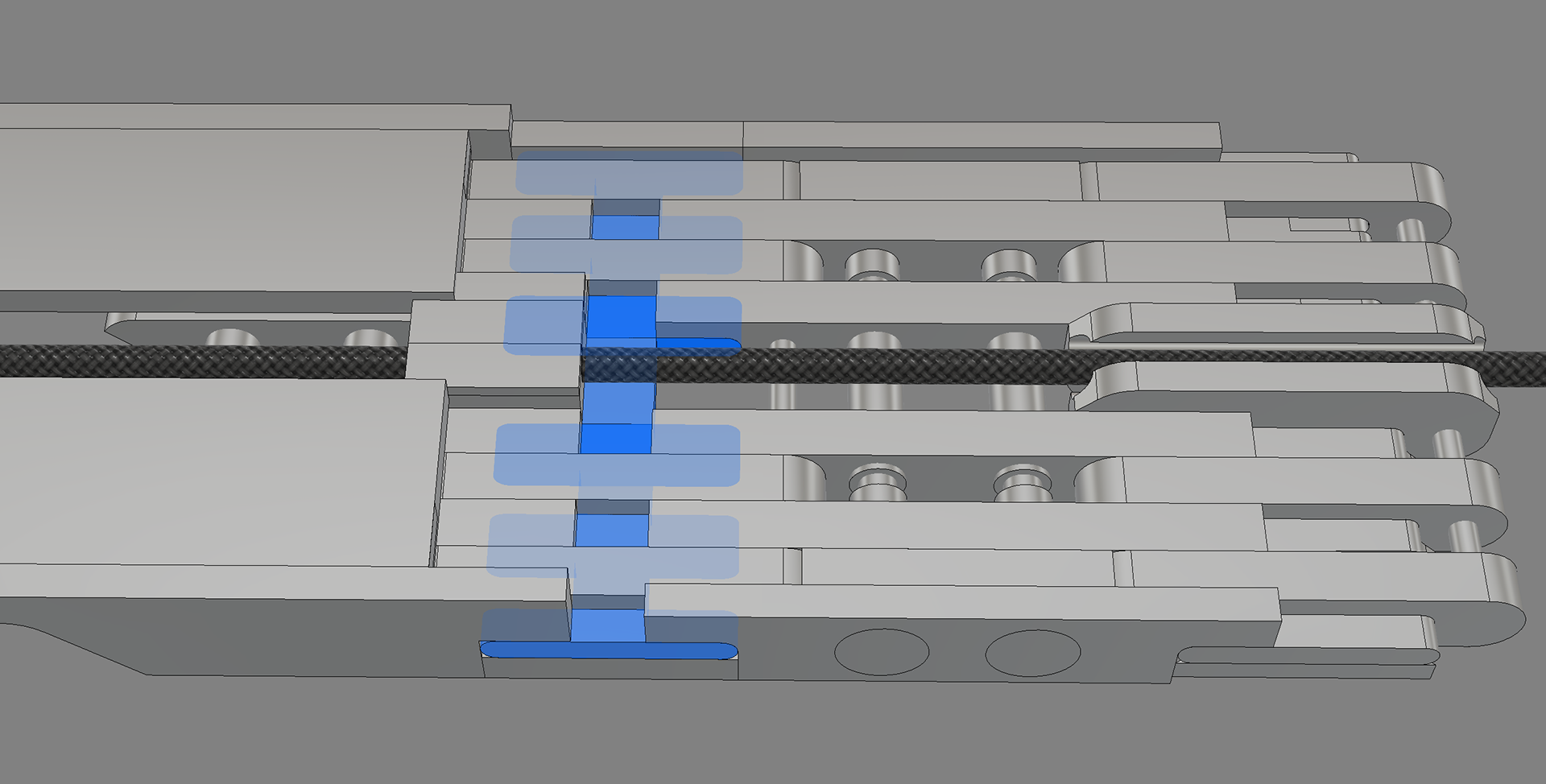

The adjustment plates are responsible for determining the overall size of the headband when worn. Each plate is attached to the one below it by two sprung couplings. The lower coupling is fixed in place, while the upper coupling can be adjusted between any of the horizontal slots in the adjustment plate. The adjustable coupling does not change position when the headband is collapsed, allowing the user to set the size once and have the headband always open to that position.

Both couplings have built in spring features to allow the adjustment and sliding plates to separate slightly, providing clearance for the earcup coupling to slide past.

The couplings connect to slots in a sliding plate, which allows both the adjustment and fork couplings to slide past each other along its entire length. Folding is accomplished by simply swapping the ends of the sliding plate that the earcup and upper headband are attached to.

When the fork coupling is slid upwards on the central plate, the fork is forced to pivot inwards to allow the headband to slide overtop of the central body of the earcup. A spring steel plate connects the fork to its coupling, and two ramp features pivot the fork when moved out of alignment with two matching slots at the bottom of the central plate.

A nylon strap (not shown) runs between each earcup to comfortably suspend the headband above the head. The strap has it's own adjustment mechanism to reduce bulk when worn and to allow for on the fly adjustment.

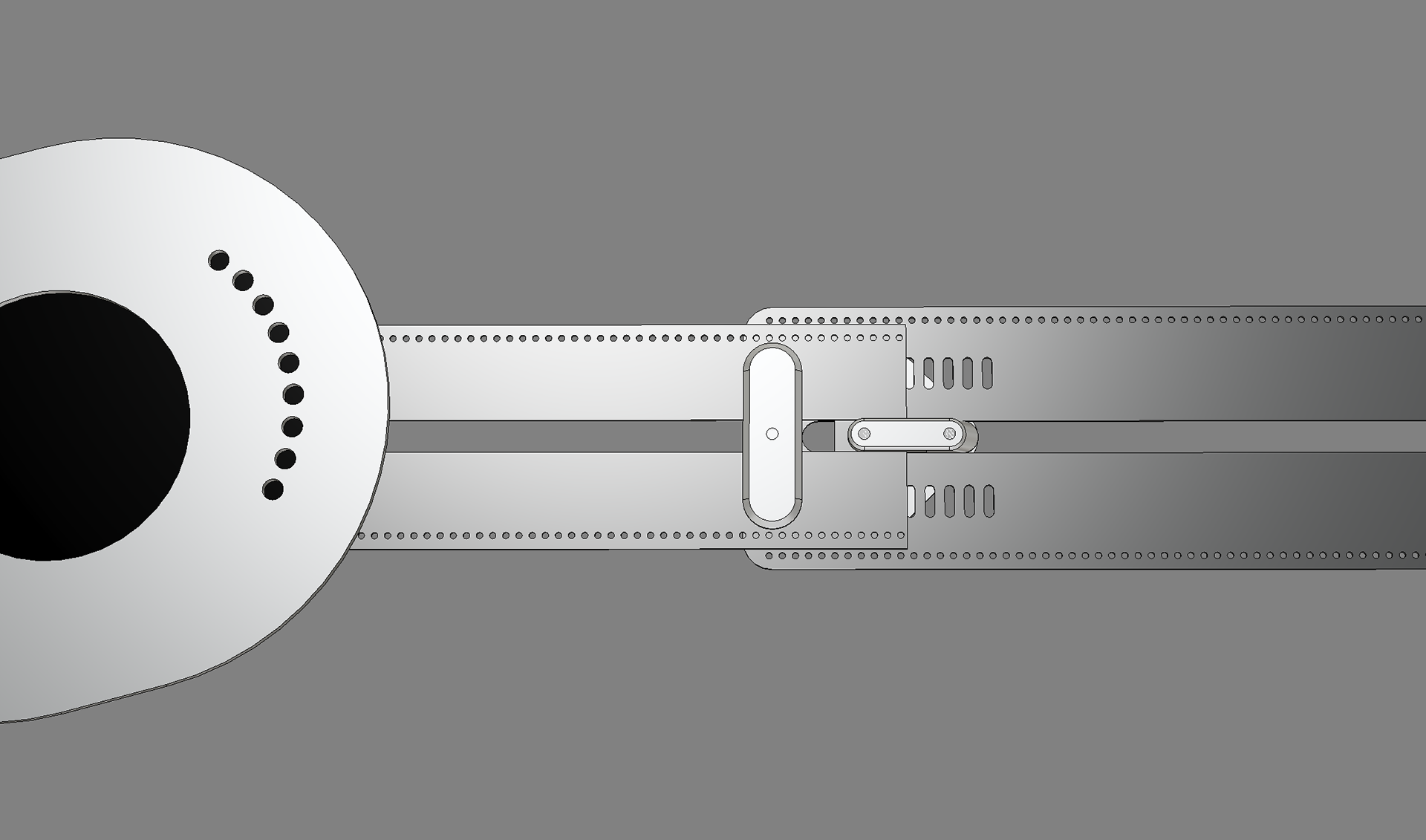

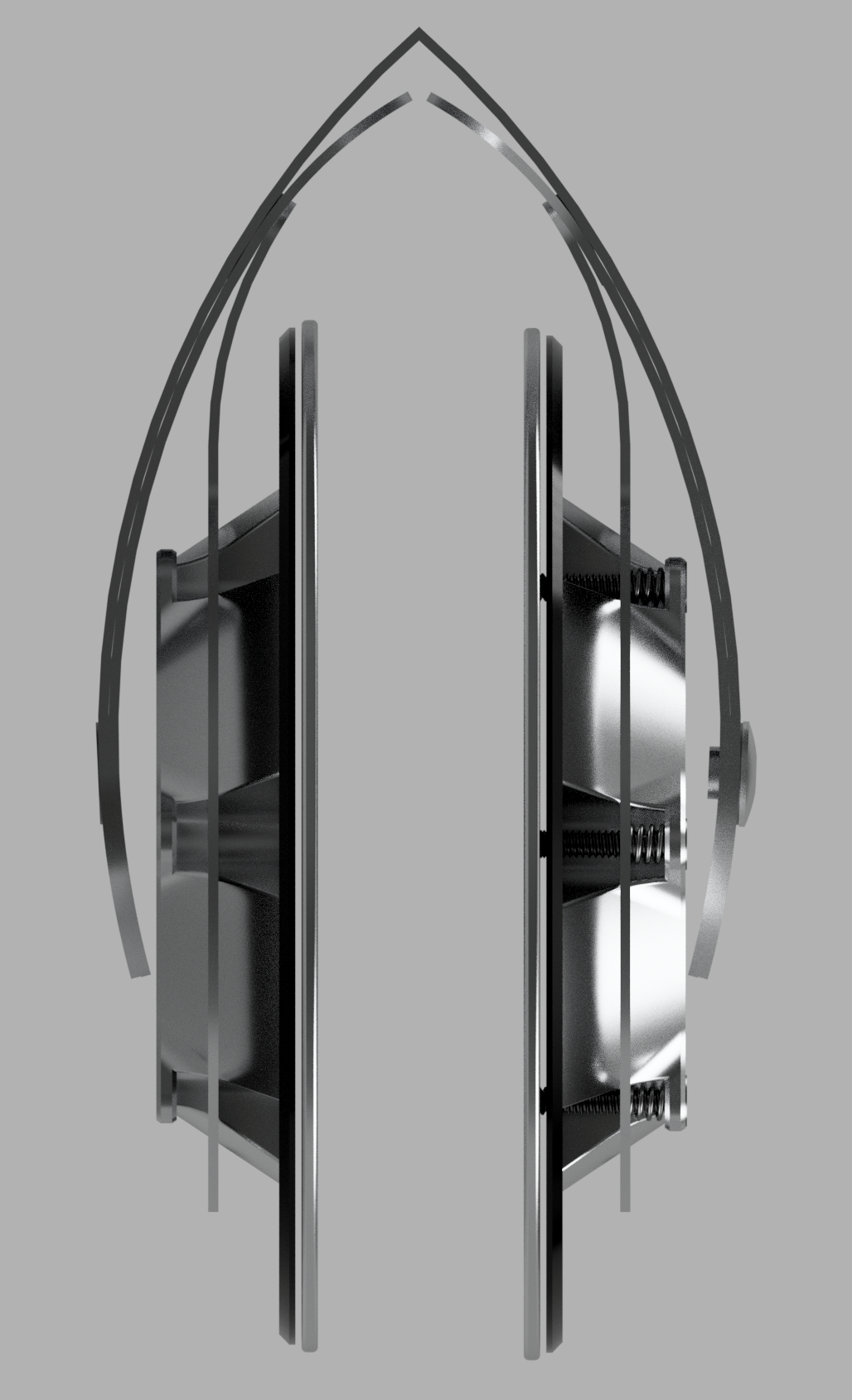

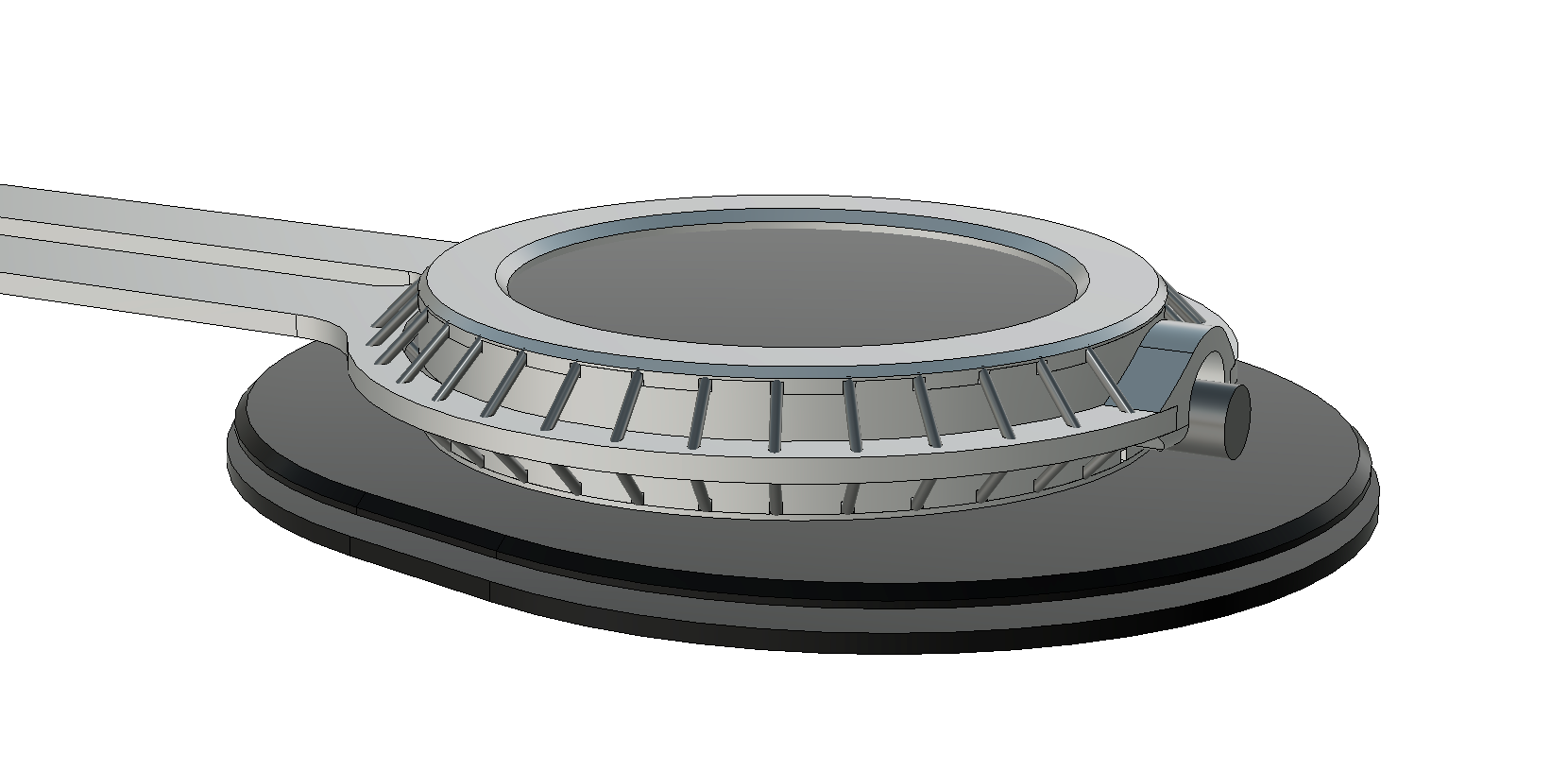

Final Earcup

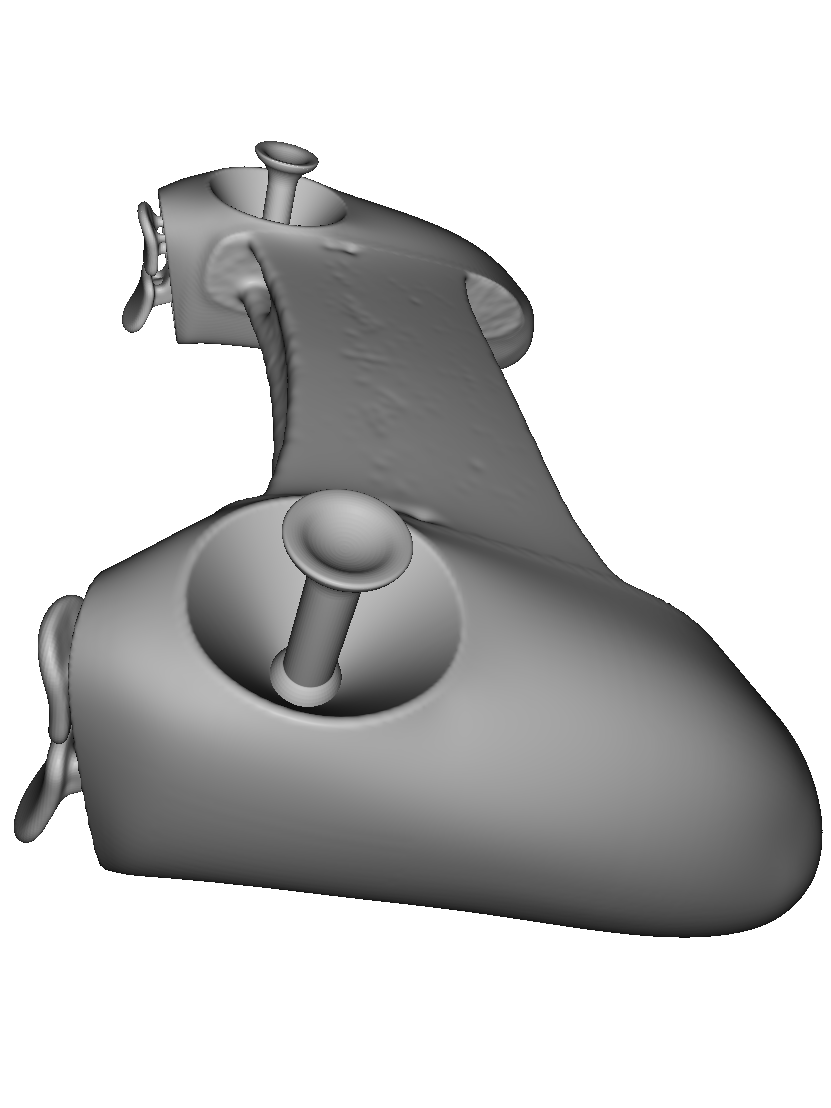

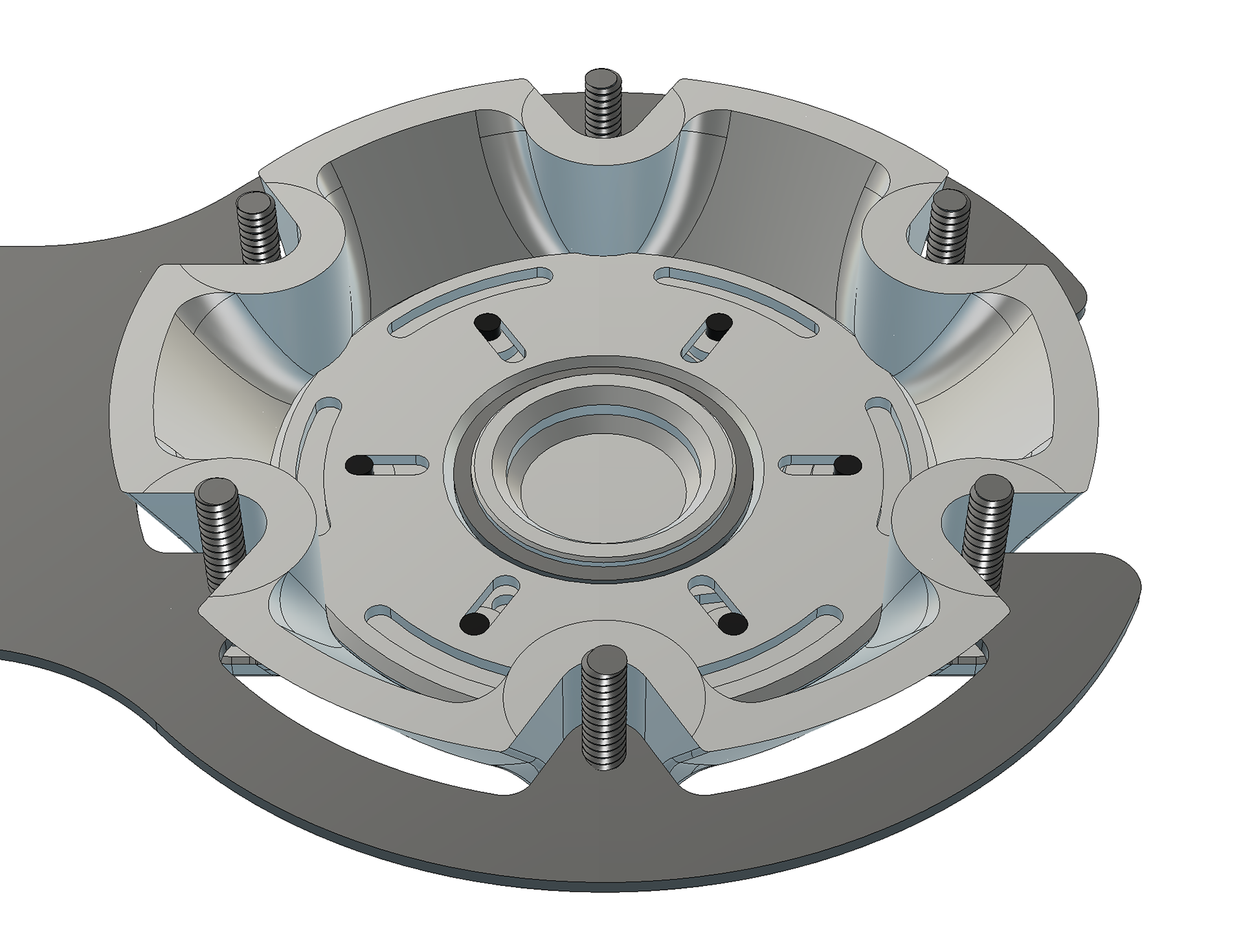

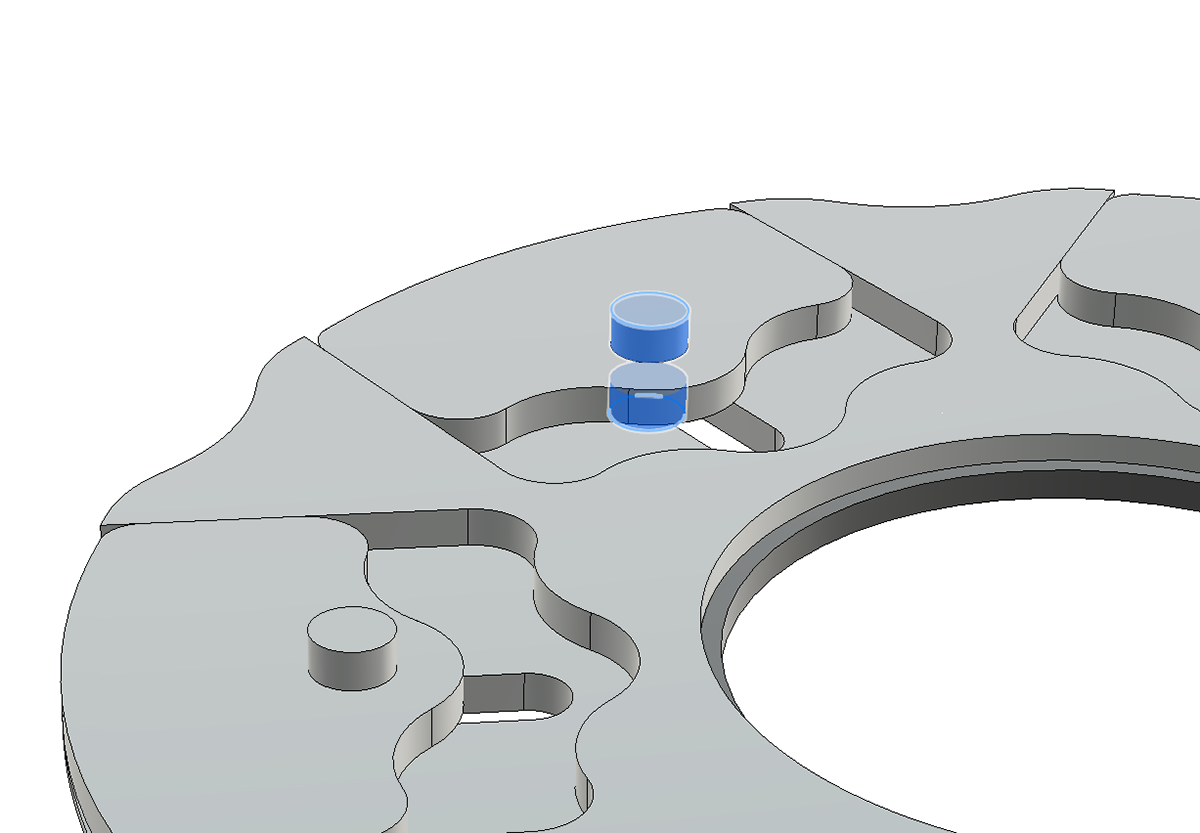

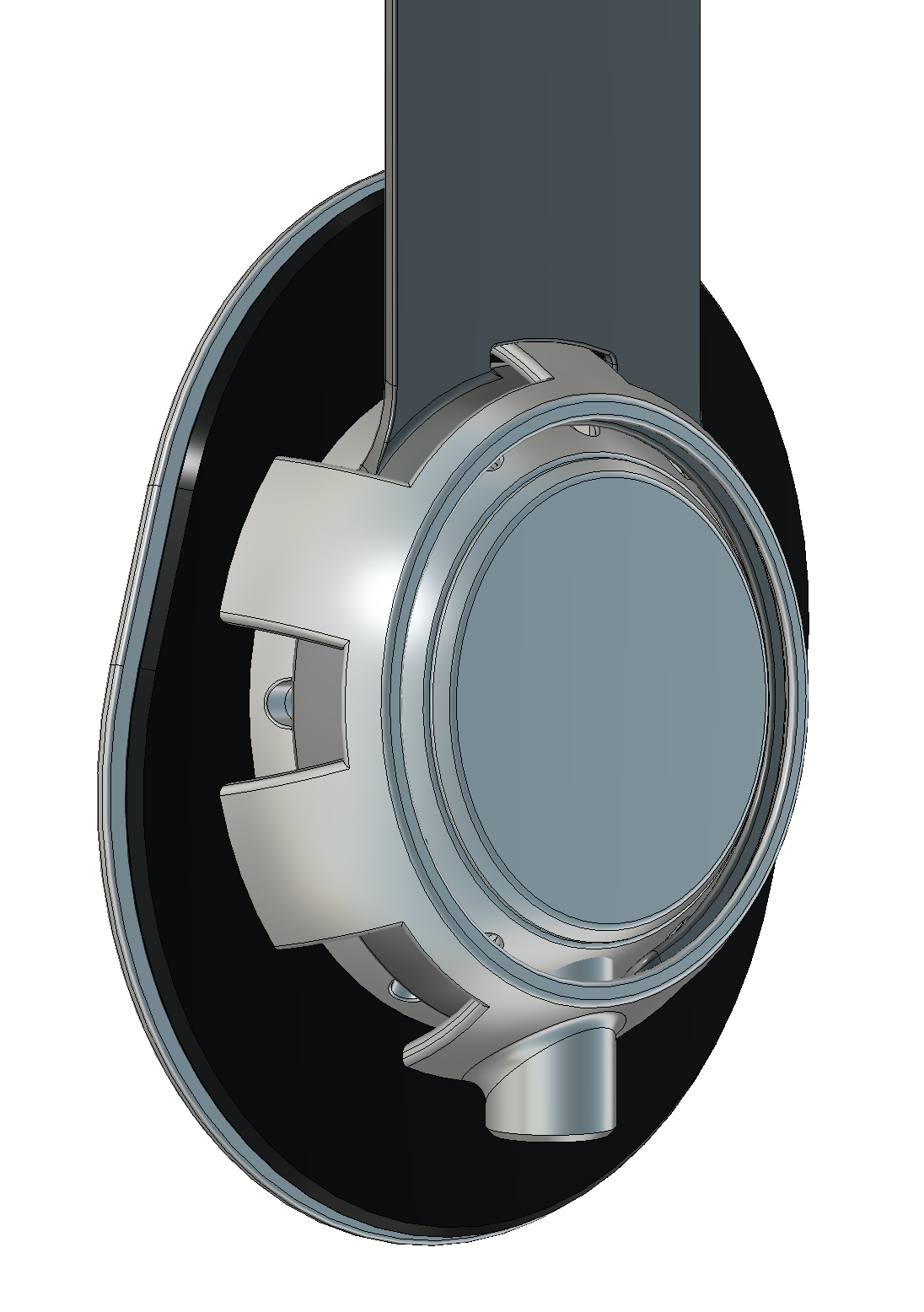

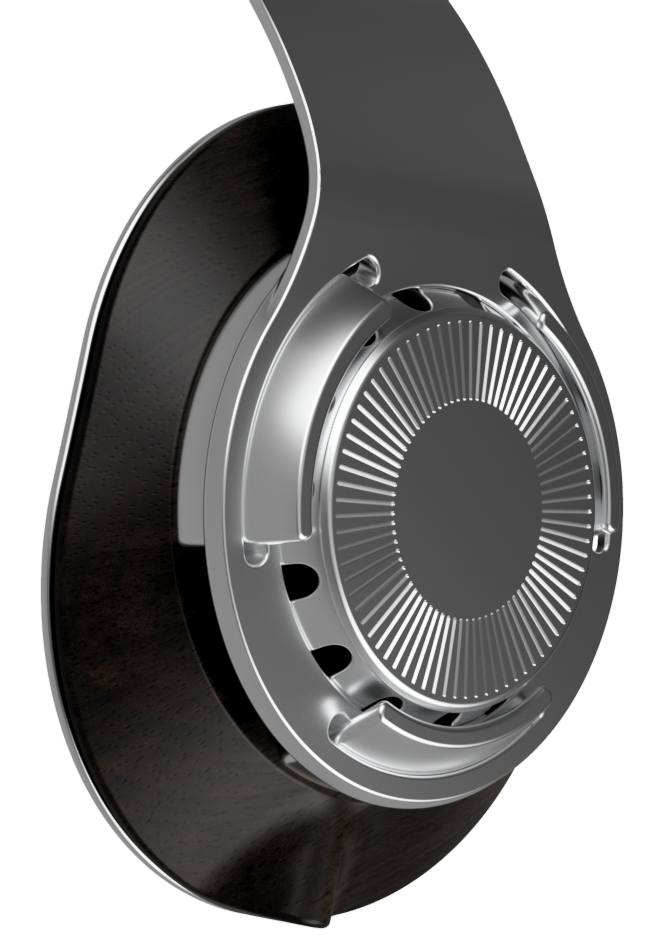

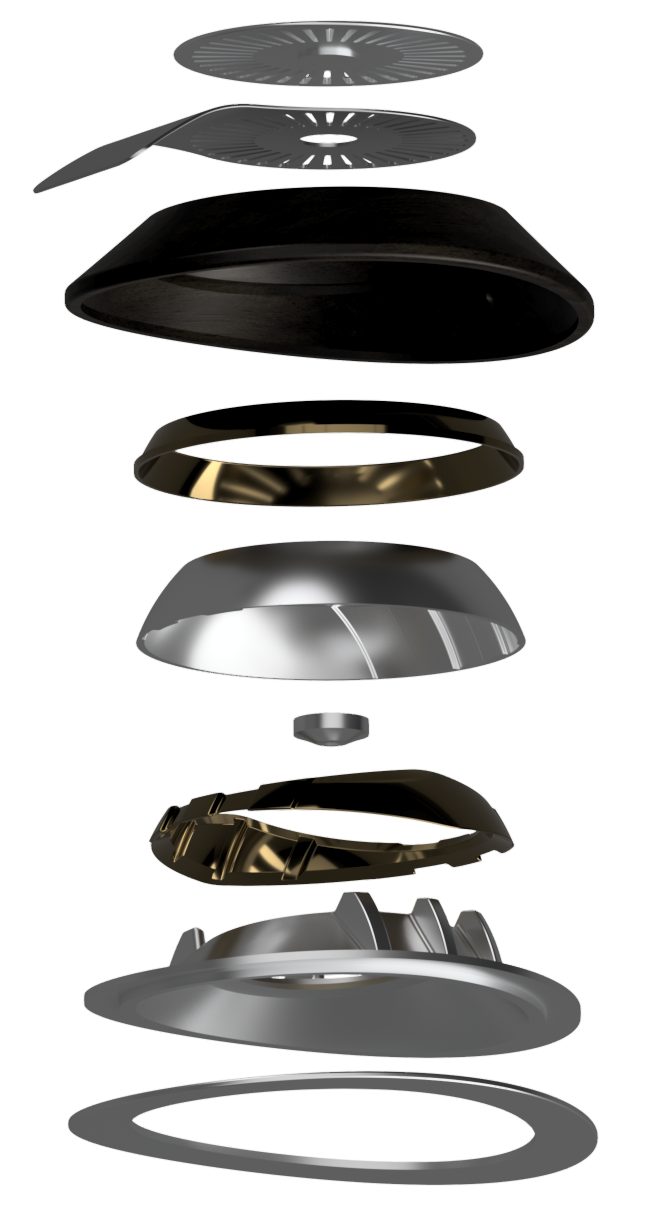

Articulation is provided by a truncated ball joint, consisting of the central body of the earcup and the fork which connects back to the band. Three retaining wings are arranged in a triangle around the center of the earcup to securely attach the fork. All mating surfaces are constructed from concentric spheres, allowing the earcup to freely pivot about 8 degrees from center in any direction.

The fork also incorporates a pin which slides vertically in a matching slot in the lower wing, preventing the fork from spinning freely. This has the side effect of forcing the fork to spin slightly when the earcup is pivoted to the side. By placing the pin at the bottom of the joint, the center of the headband is pushed forward when the earcups are turned back, more effectively hugging the head; this small change in geometry helps make the headphones more comfortable and secure for a greater variety of heads.

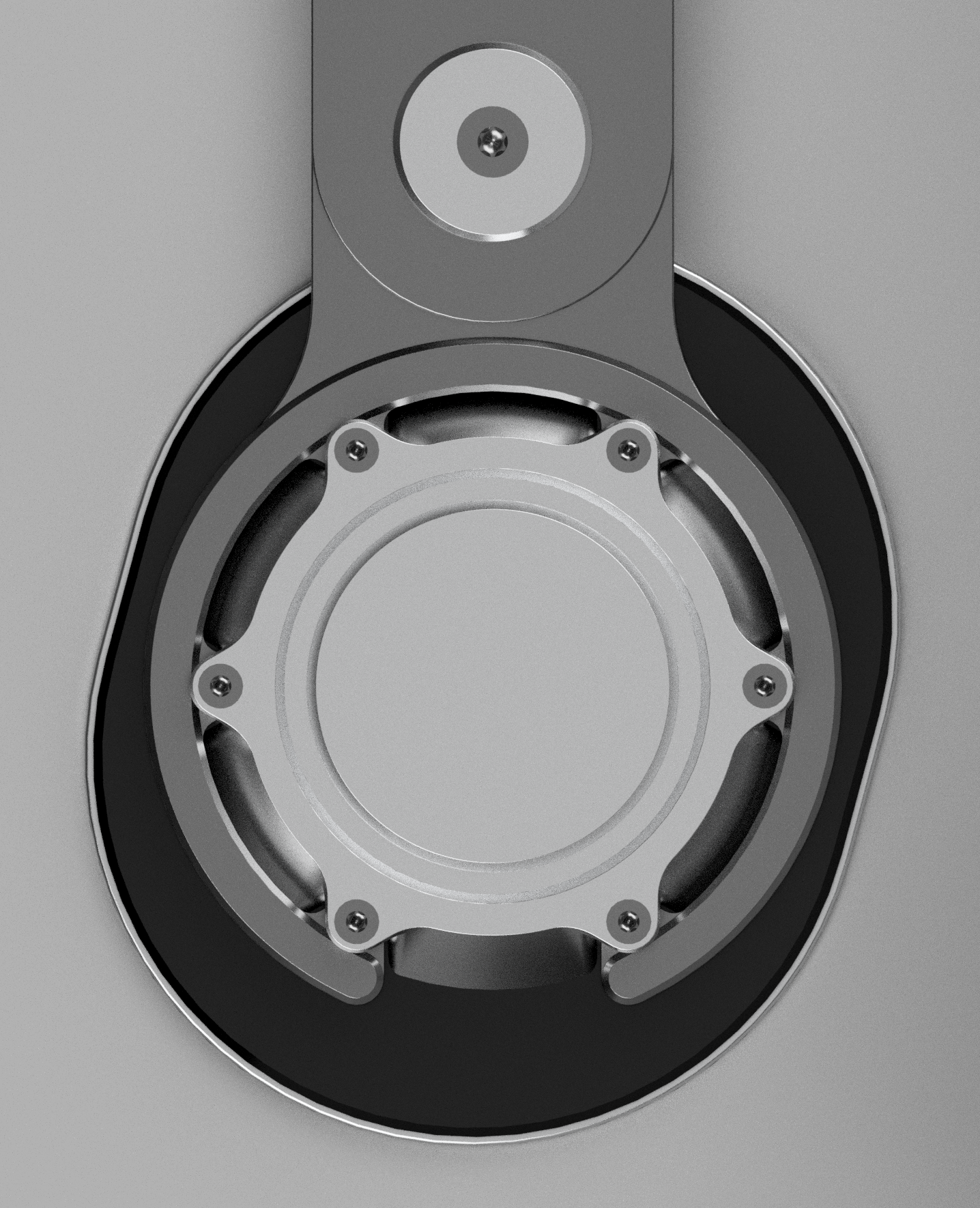

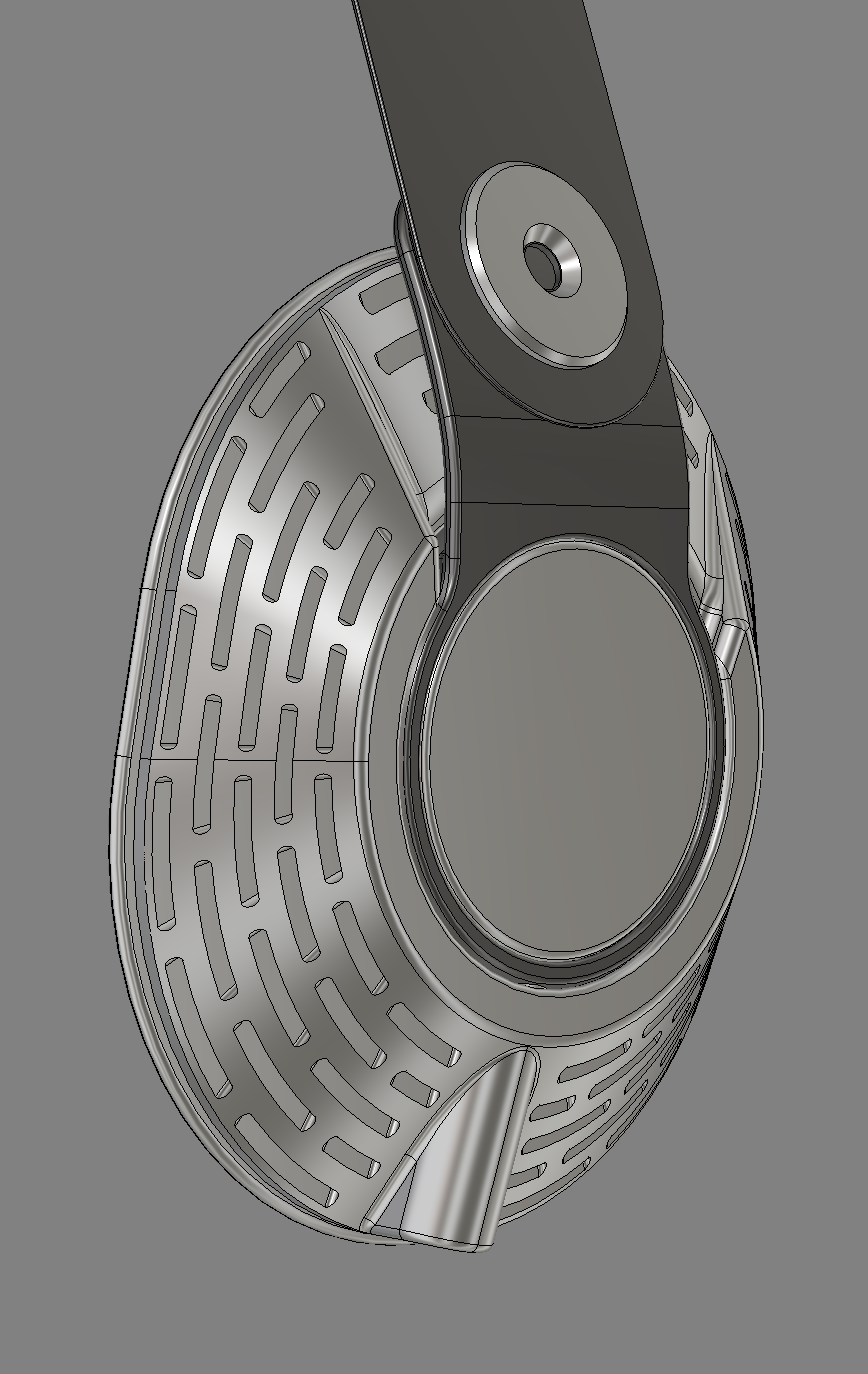

Truncated ball joint earcup

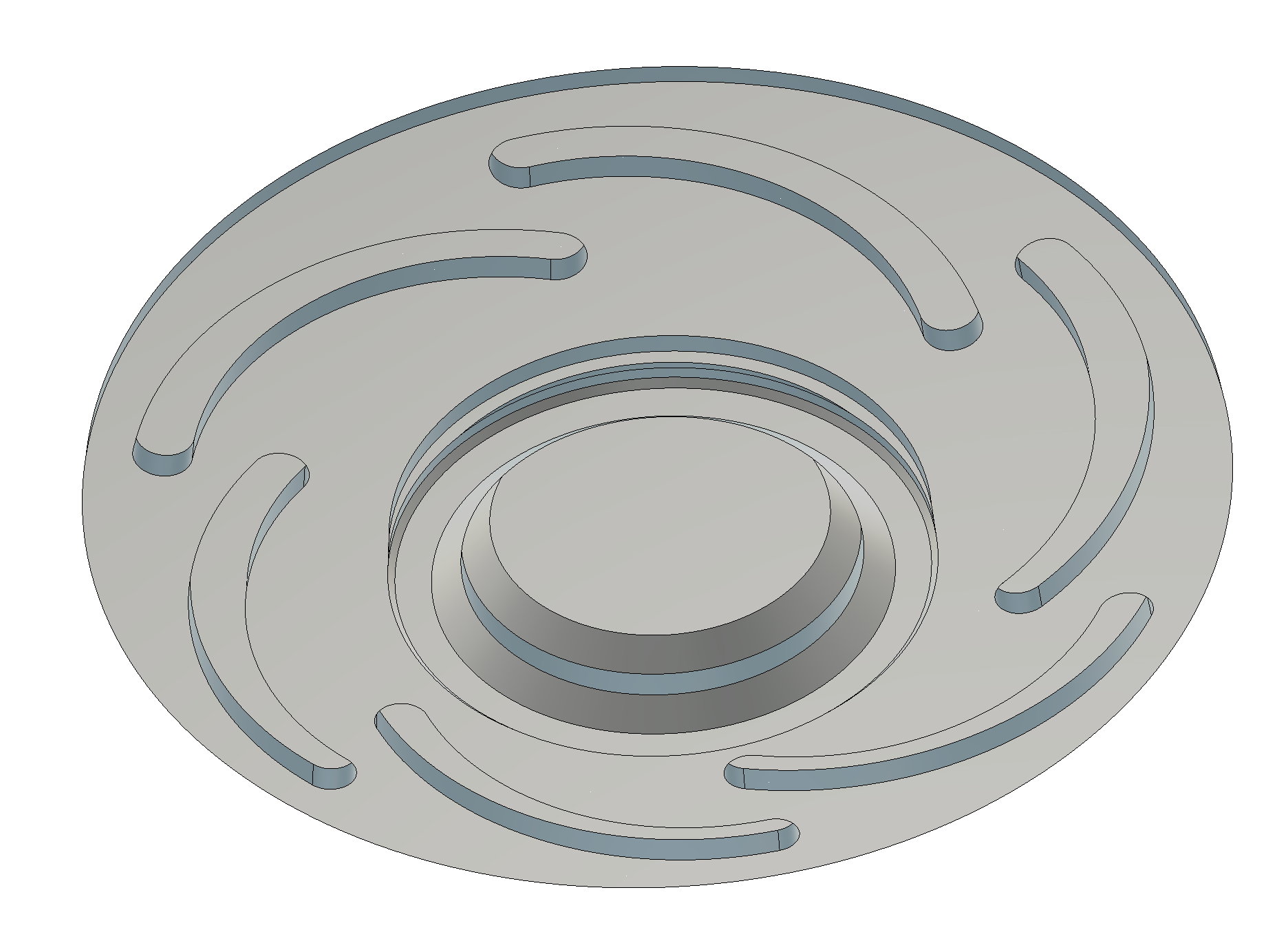

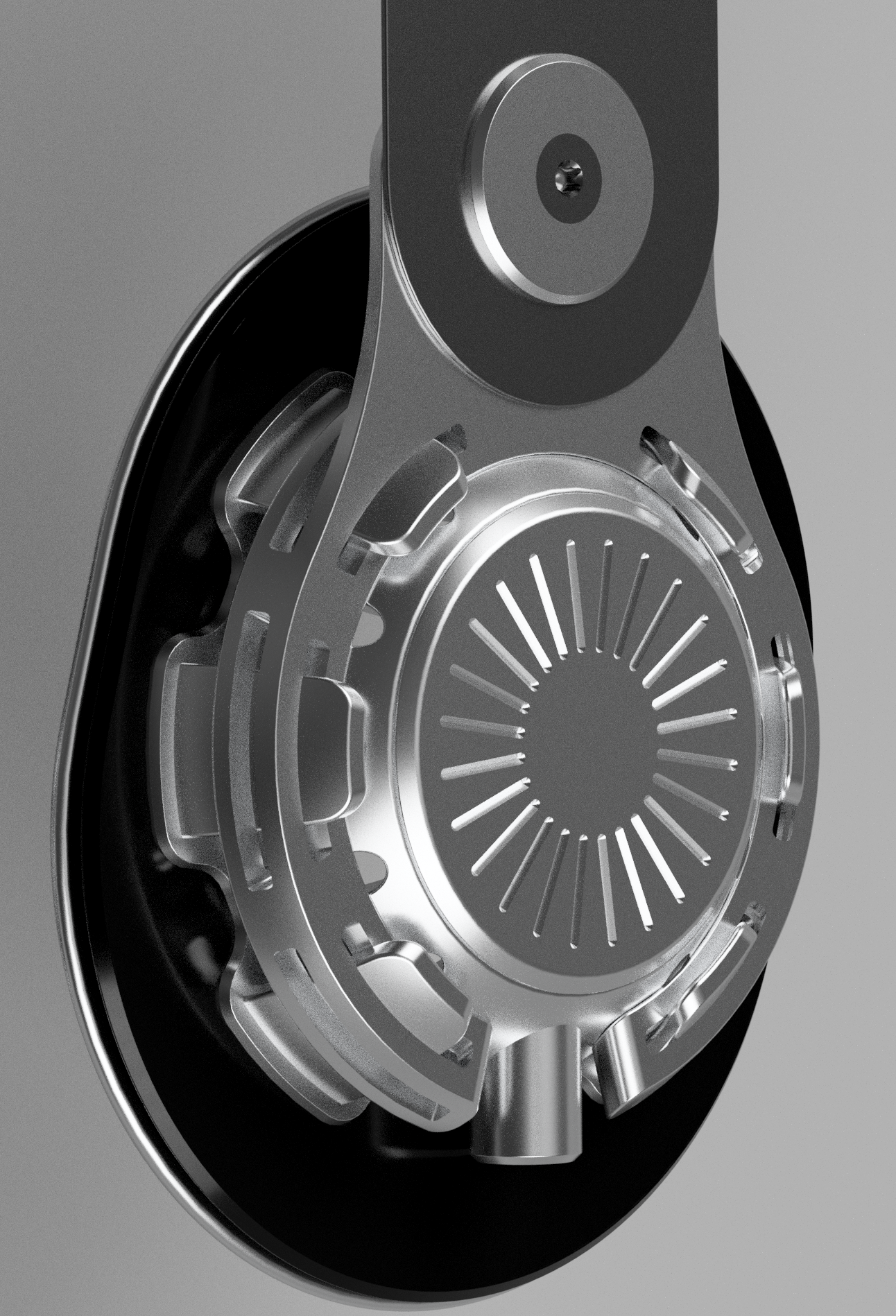

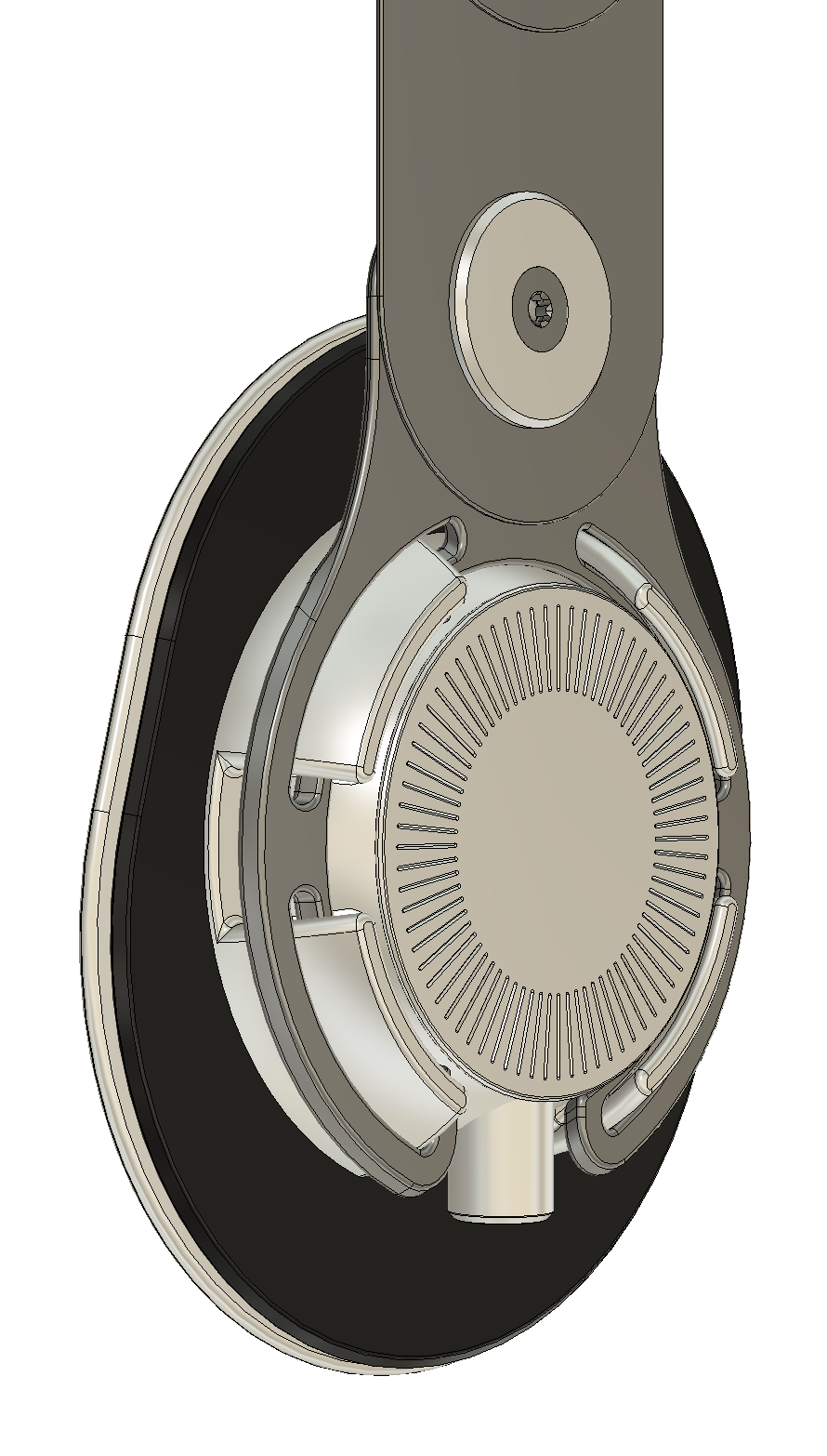

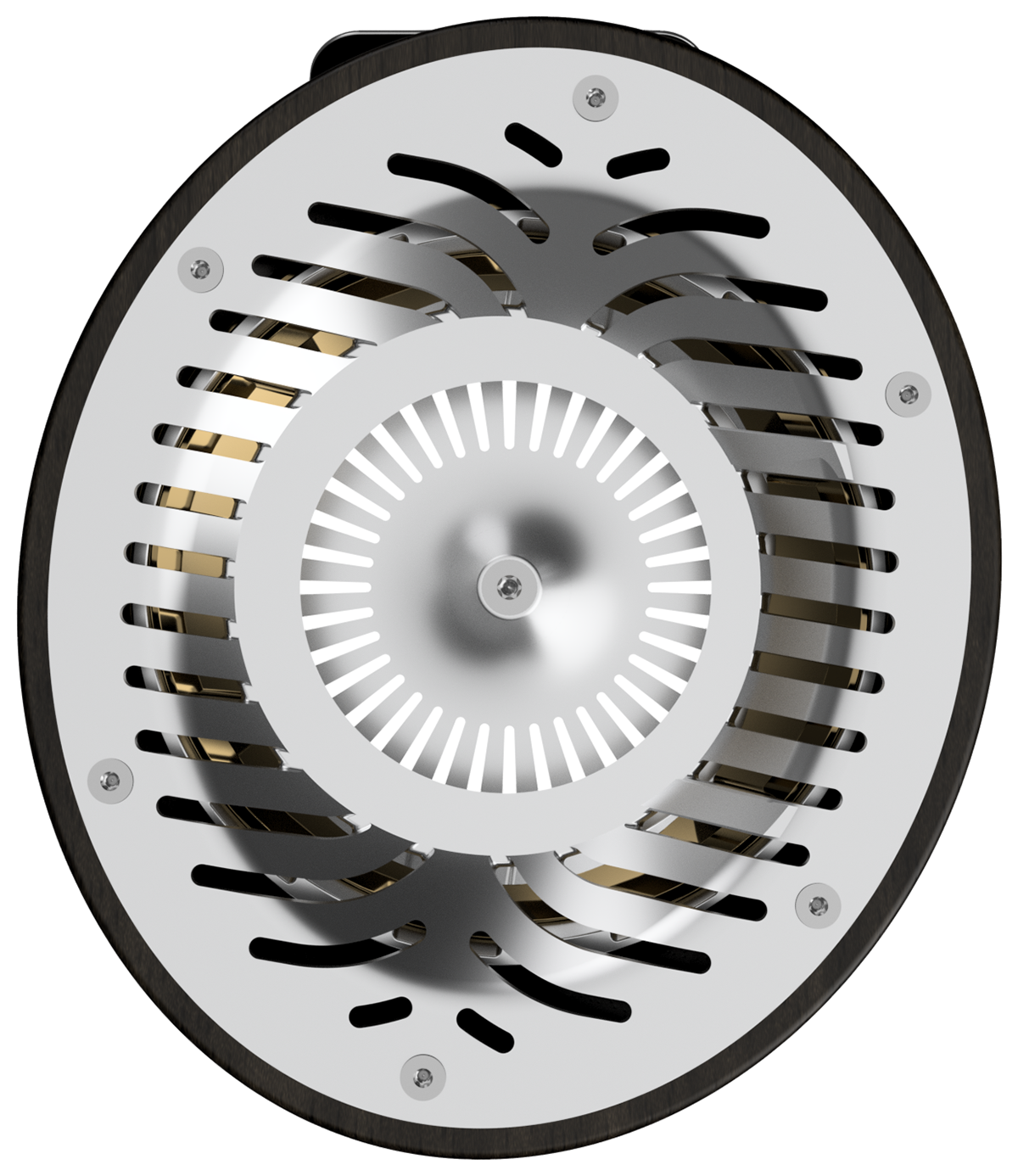

The central body consists of two shells, with the inner able to be rotated by the ridged top plate to open or close the vent slots around the circumference of the housing, adjusting its acoustic transparency. This feature allows the sound profile of the headphones to be adjusted, but more importantly increases versatility. For office or library use noise isolation is important both for the user and those around them, but in other situations, like biking or traveling, some transparency is preferable to allow the user to be more aware of their surroundings.

To reduce the feeling of "stuffiness" created by many closed back headphones, an acoustic lens is built into the top of the interior shell; this lens deflects the negative half of the driver output radially, either out through the slots around the edge when opened, or further down into the acoustic dampening foam at the base of the earcup when closed. This reduces interference between the positive and negative output waveforms of the driver, resulting in cleaner sound.

Cross section showing main ball joint and brass alignment ring, openness adjustment mechanism

Functional Prototype