The main goal of this project was to develop tools for the manufacture of small sheet metal components for the headband of an over ear headphone. This involved learning about the properties of sheet metal and existing methods for bending and stamping parts. The final parts must have high dimensional accuracy, and the production process must be repeatable and streamlined enough for small scale production. Initially, I designed a modular sheet metal brake intended to complete all of the necessary forming operations, as this minimizes the number of tools to be built and allows for flexibility if the parts to be made change. To maximize rigidity, the mouth of the brake is approximately 5 cm wide, slightly wider than the largest part.

Preliminary sheet metal brake design

During this process I also experimented with bending sheet metal by hand, and constructed a cardboard prototype of the fully assembled sheet metal design in order to assess its basic form, functionality, and ease of assembly.

Headband Prototype

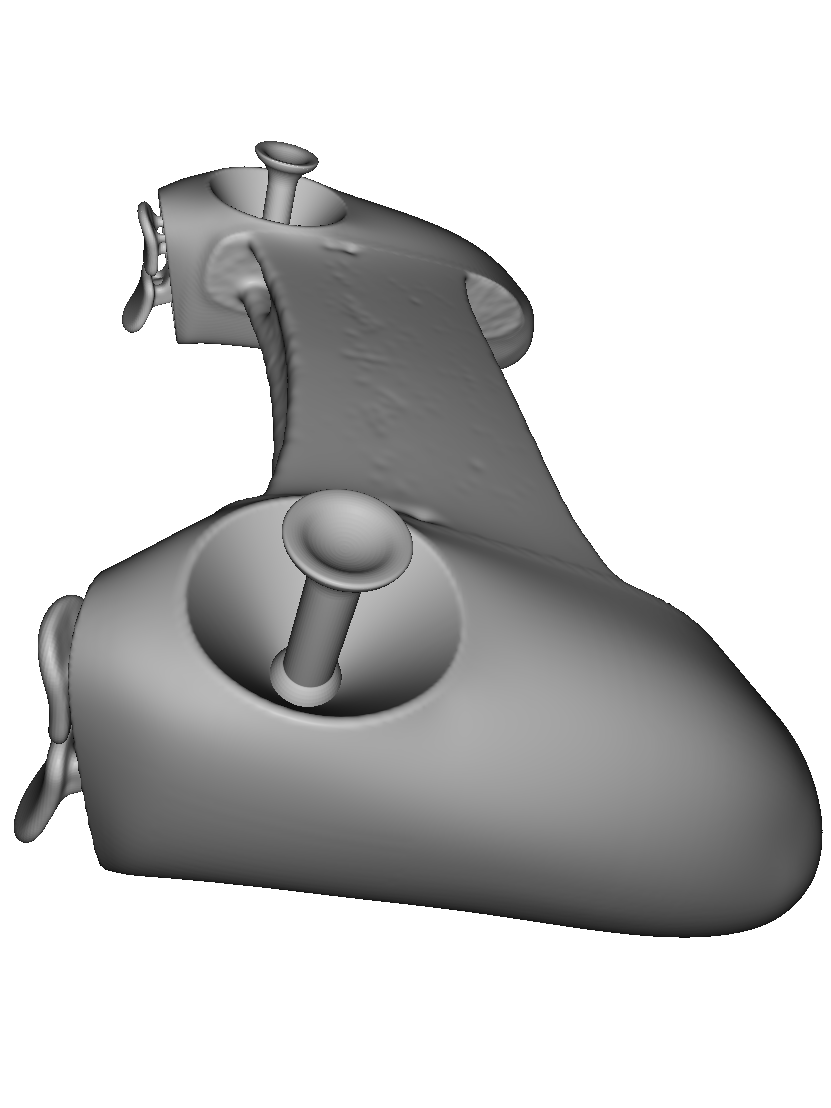

After more research and testing I identified some shortcomings in the initial bending strategy. Many of the parts require complex and accurate bends that would be difficult to accomplish consistently by hand. Several parts also have small offset jogs, a bend that is difficult to accomplish using a brake due mostly to work holding issues. In light of this, I decided to create a set of custom forming dies to supplement the above brake. Though this strategy will require a separate tool for each component, the variety of bends that the brake must be able to complete can be reduced, simplifying its design. The dies will initially be 3d printed, and once their design is finalized they will be milled from aluminum, or possibly a machinable plastic like Delrin provided its strength is adequate.

Forming Die for One of The Components

Finished Component

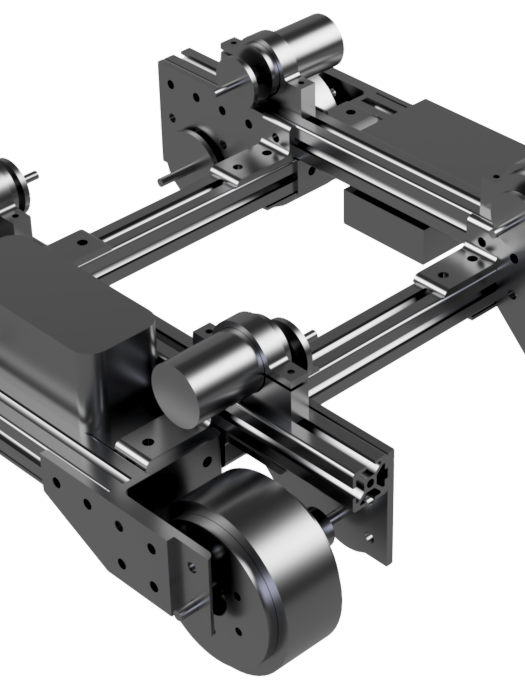

In addition to simplification, the initial design also required revision to make it more easily manufacturable. The second iteration incorporates off the shelf door hinges, with all other parts made from flat sheet metal that will be laser cut. Since the axis of rotation of the hinge must be precisely located to ensure accurate bends, thin shims will be used to offset the hinges from the structural plates to which they attach. This design also allows for different thicknesses of sheet metal to be bent by changing the shim thickness.

Revised Brake Design